Description

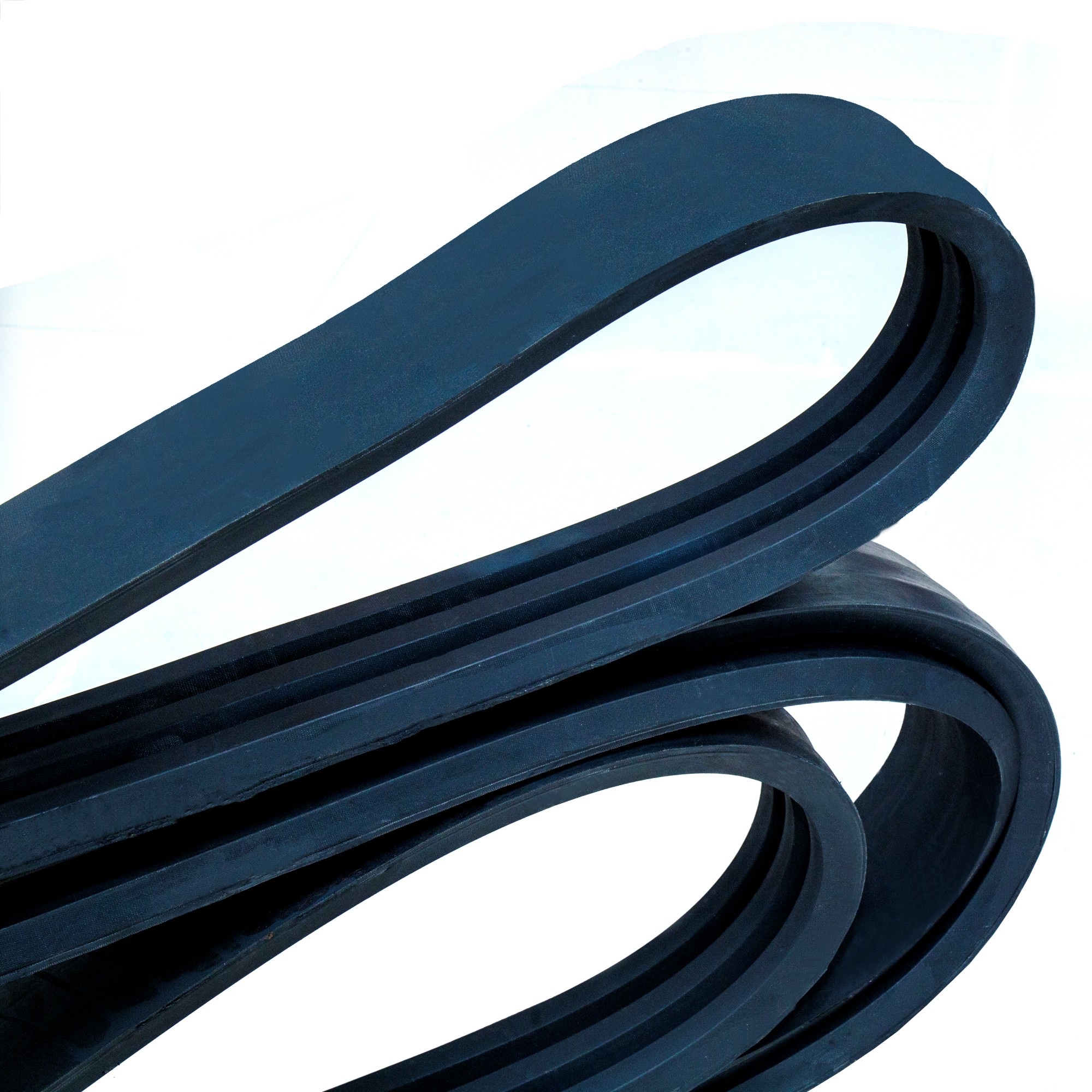

Construction:

Specially compounded wrapped construction is ideal for clutching operations with static-dissipation, oil, and heat resistance

Engineered synthetic rubber compound, specifically compounded for excellent wear resistance, proven through thousands of hours of testing.

Tensile cord/Aramid cord is allowed for production

The body rubber compound is a highly engineered synthetic rubber compound, specially compounded for cool running, flexibility, crack resistance, and excellent bonding to the outer fabric and tensile/Aramid cords.

The Tie-Band backing joins the individual belts.

Double ply tie-band permanently bonds belts enabling single unit functioning for smoother operation, shock absorption and elimination of belt whip and turnover

Features/Advantages:

Superior power transmission capacity up to 60% more than the standard single Belts

Prevents damages and jumping off the sheaves due to excessive belt flaps.

Enhances stability and prevents belts from turning over or coming off the drive. Minimizes vibration.

Eliminates changes of mismatch in length

High adhesion strength beween the band and belts

REACH & RoHS compliant, provides an eco-friendly system

Anti-static, Oil and Heat Resistant

Temperature range: -30°C to +100°C

Applications:

Severe vibration drives, such as rock crushers, agricultural equipment, industrial compressors, generators and hydraulic pumps

Stone crushers, reciprocating compressors, generator sets, saws, pumps cold forging machine, foerstry woodcutters,woodchipers etc

Agricultural drives, harvestor combines

V-flat drives, vertical shaft drives

Surface Miners for conveyor systems

Dimensions&Product Range:

| Section | Top Width mm |

Belt Height mm |

Angle Deg |

| AJ/HA | 13 | 10 | 40 |

| BJ/HB | 16 | 13 | 40 |

| CJ/HC | 22 | 17 | 40 |

| DJ/HD | 32 | 21 | 40 |

| HSPZ(SPZJ) | 10 | 8.5 | 40 |

| HSPA(SPAJ) | 13 | 12 | 40 |

| HSPB(SPBJ) | 17 | 16 | 40 |

| HSPC(SPCJ) | 22 | 20 | 40 |

| 3V/9J | 9.7 | 9.7 | 40 |

| 5V/15J | 15.7 | 15.7 | 40 |

| 8V/25J | 25.4 | 25.4 | 40 |