Description

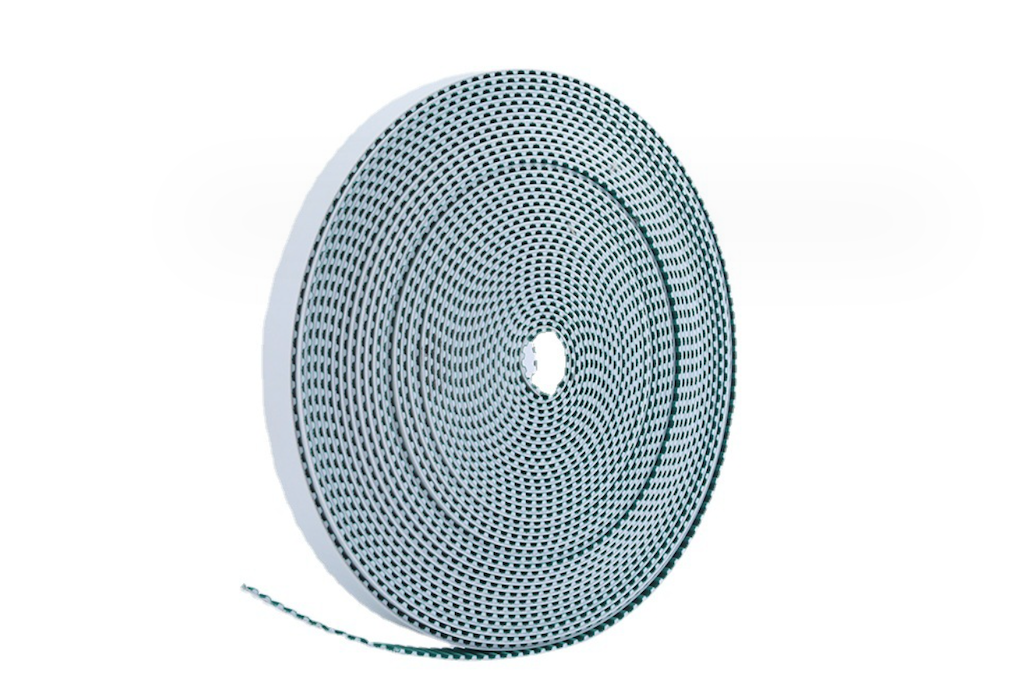

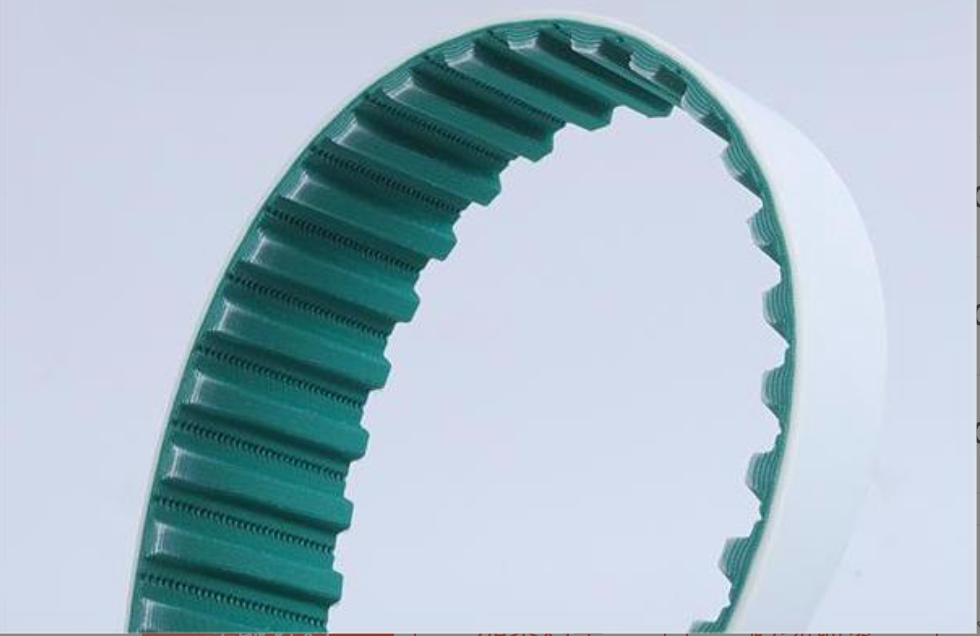

PU Timing Belt’s manufacturing process-cast which is moulded polyurethane.

Advantages of PU Timing Belt:

- The cast polyurethane timing belt is an exact image of the precision engineered mould. High pitch accuracy is achieved over the entire belt. The technology is particularly suitable for applications requiring high levels of angular accuracy, smooth running characteristics, high rotational speeds and long life.

- Excellent linearity with high pitch accuracy and repeatability allows the length to be optimised by adjusting the cord tension.

- The casting method combines with the capillary effect, producing an exceptionally high strength bond with the steel tension members.

- The high reproduction quality of the cast polyurethane process enables fine contoured features and smaller belt pitches to be moulded, Double- side belts and profiled flights on the back of the belt can be moulded simultaneously.

- The process produces an effective belt width of up to 300mm.

- Belt lengths from 55mm to 6000mm endless length.

- Mingsen polyurethane timing belts are used across a very wide range of applications for the transmission of synchronous rotary motion in power transmission systems, servo and motion controls, conveyors and transfer lines. They operate in a rotational speed range of up to 20, 000 rpm.

Properties of Belts:

| Project | Trapezoid tooth | Arc tooth | |||||||||

| XL | L | H | XH | XXH | 3M | 5M | 8M | 14M | 20M | ||

| Tensile strength≥(N/mm) | 80 | 120 | 270 | 380 | 450 | 90 | 160 | 300 | 400 | 520 | |

| Elongation at reference load |

N Reference load | 60 | 90 | 220 | 300 | 360 | 70 | 130 | 240 | 320 | 410 |

| Elongation≤% | 4.0 | ||||||||||

| Hardness(Shore A) | 75±5 | ||||||||||

| Adhesion strength of cloth (N/mm) | 5 | 6.5 | 8 | 10 | 12 | – | 6 | 10 | 12 | 15 | |

| Core rope strength of cloth(N/mm) | 200 | 300 | 600 | 800 | 1500 | – | 400 | 700 | 1200 | 1600 | |

| Gear shearing intensity(N/mm) | 50 | 60 | 70 | 75 | 90 | – | 50 | 60 | 80 | 100 | |

Applications include:

- Office machinery

- Electronic data processing equipment(EDP)

- Textile machinery

- Wood processing machinery

- Machine tools

- Printing machinery

- Pumps

- Compressors

- Building machinery