Description

Straight Warp( SW ) Conveyor Belt adapts 1-2plies SW canvass to replace multiplies EP or Nylon canvass, which can save 7-17% full thickness, to improve the sinuosity of the belt. I can make the belt run well with smaller pulleys, which make the length of the belt reach 400-500meters, to save the loss of the production.

With special weaving method, SW fabric layer has a good performance of high tension strength, and the working elongation of the belt can be reduced a lot. The special structure of straight warp can absorb impact higher than EP or Nylon material, which prolong the service life of the belt.

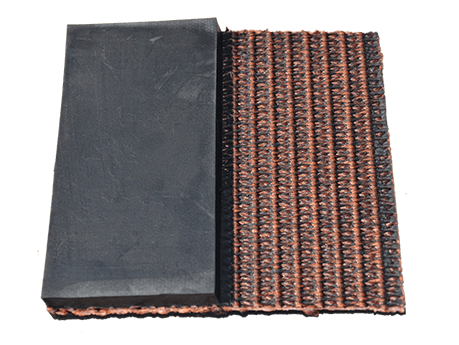

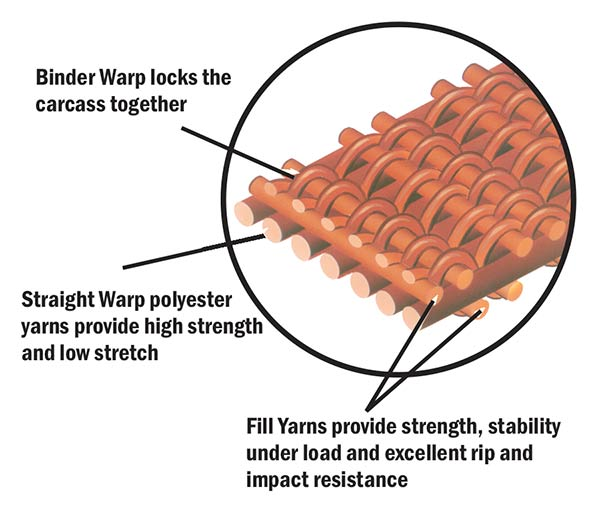

Construction:

Binder warp yarn locks the carcass together

Straight warp polyester yarns provide high strength and low stretch

Fill yarns provide strength, stability under load and excellent rip and impact resistance

Features:

Light

To compare with the belts having the same grade of the tensile strength, the SW belt provides 10%~20% less weight, power saving to minimize the load of conveyor accessories, so as to reach the efficiency of saving power source and cost down.

Thin

Use one or two plies replace the multi-plies construction make total thickness 7%~17% thinner, increase the strength smoothly under the smaller. This can help the belt running smoothly under the smaller pully. Each roll length can be 400~500m to reduce the waste.

Powerful

Use a special weave type of high-denier fiber to raise the tensile strength of the fabric, reduce the working elongation and replace the Multi-plies construction belts.

Tough

The special construction of the Straight Warp provides more impact absorption than EP or NN products, and increase the belt service life.

Straight Warp Conveyor Belt Specifications and Applications:

| SW | STRENGTH | APPLICABLE RUBBER GRADE | APPLICATIONS |

| FABRIC X PLIES | (KG/CM, KN/M, N/MM) | ||

| SW400 x 1P | 400 ↑ | Abrasion Resistant | Steel |

| SW630 x 1P | 630 ↑ | Oil Resistant | Mining |

| SW800 x 1P | 800 ↑ | Flame Resistant | Coal |

| SW1000 x 1P | 1000 ↑ | Cold Resistant | Cement Plant |

| SW400 x 2P | 800 ↑ | Heat Resistant | Paper Industry |

| SW630 x 2P | 1200 ↑ | Impact Resistant | Port |

| SW800 x 2P | 1600 ↑ | Chemical Resistant | Power Plant |

| SW1000 x 2P | 2000 ↑ | Anti-Static Resistant | Impact Conveying Heavy Industry |