Description

Steel cord conveyor belt is mainly product in Mingsen Belt offers the steel cord conveyor belt for heavy load transportation among other uses. The conveyor is ideal for transporting material for the coal, harbor, metallurgy, power station and chemical field among others.

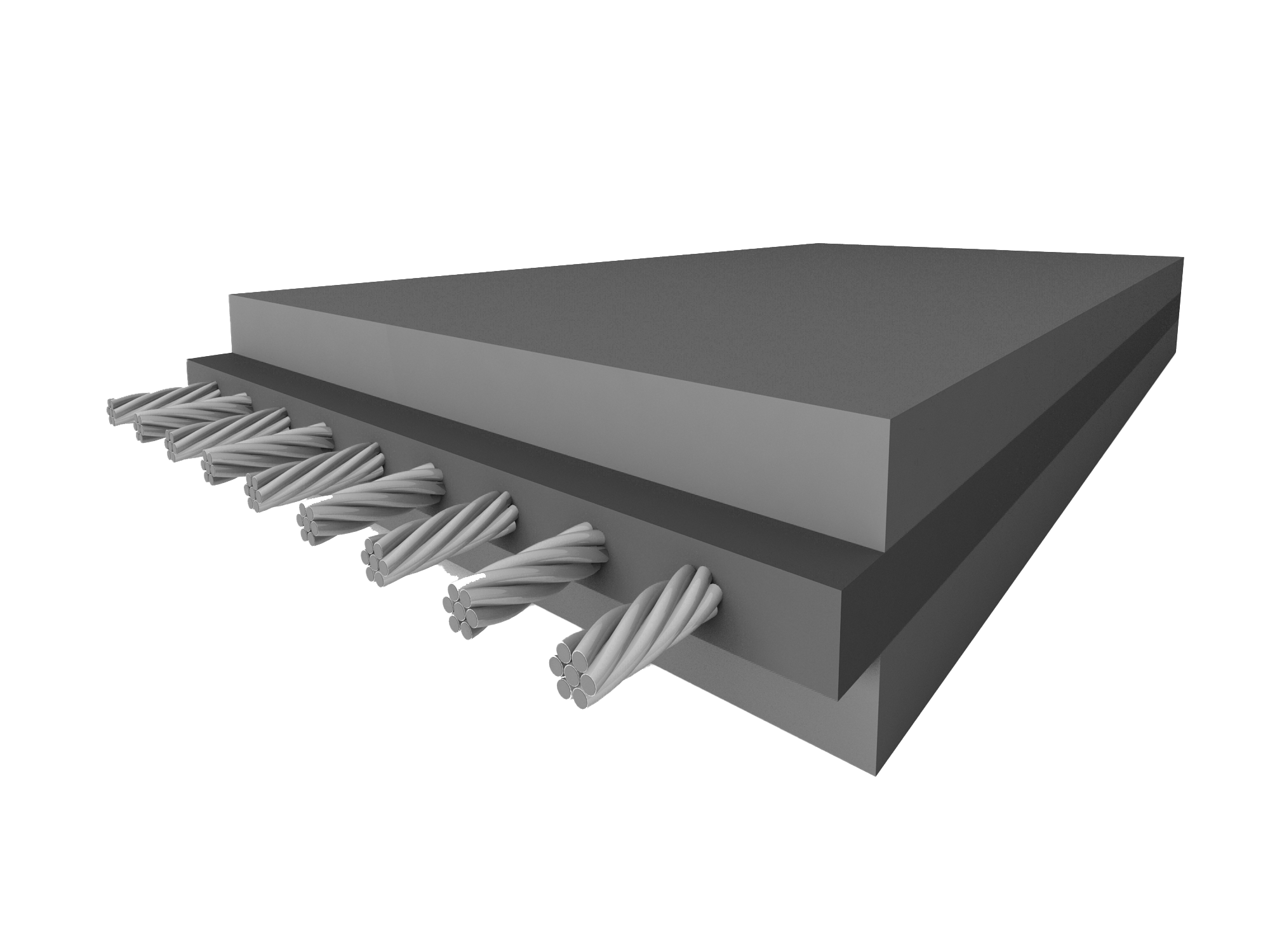

Belt reinforcement consists of galvanized steel cord and core rubber which possesses superior adhesive property. Belt body comprises the reinforcement covered with top and bottom rubber layers. Steel cord is composed of left and right twisting wire and arranged evenly and longitudinally in the belt.

Also preferable for short distance transportation, the belt can travel long distances at high speeds and offers excellent flexibility and efficiency. Manufactured to DIN,ISO, AS standards, the belt can also be used to transport materials for special occasions.

Applications:

Conveyance of crushed rock, aggregate, sand, limestone, ore, etc

Features:

High Belt Strength: Available belt strength ranges from 500N/mm up to 10,000N/mm covering a variety of applications.

Available Cover Compounds: Offers a wide range of abrasion, impact, cut & gouge, temperature, flame, and other socialized grades

Low Elongation: Realize minimum take up distance, best suited for long distance or other specialized conveyors with short transitions, small pulleys and yet high throughput rates.

Production Range:

Tensile strength : ST500-ST10,000 N/mm

Max. Belt width : 3,200mm

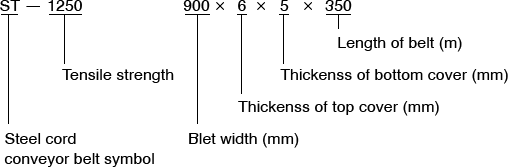

Belt specification symbols:

Main technical parameters of steel cord conveyor belt:

| Specfications and technical parameters | ST 630 | ST 800 | ST 1000 | ST 1250 | ST 1600 | ST 2000 | ST 2500 | ST 3150 | ST 3500 | ST 4000 | ST 4500 | ST 5000 | ST 5400 | ST 6300 | ST 7000 | ST 7500 |

| The longitudinal tensile strength(mm) | 630 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 | 3100 | 3500 | 4000 | 4500 | 5000 | 5400 | 6300 | 7000 | 7500 |

| Wire rope maximum nominal diameter(mm) | 3 | 3.5 | 4 | 4.5 | 5 | 6 | 7.5 | 8.1 | 8.6 | 8.9 | 9.7 | 10.9 | 11.3 | 12.3 | 13.5 | 15 |

| Wire rope spacing(mm) | 10 | 10 | 12 | 12 | 12 | 12 | 15 | 15 | 15 | 15 | 16 | 17 | 17 | 18 | 19 | 21 |

| Covered in gue thickness(mm) | 5 | 5 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 8 | 8 | 8.5 | 9 | 10 | 10 | 10 |

| Under the cover rubber thickness(mm) | 5 | 5 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 8 | 8 | 8.5 | 9 | 10 | 10 | 10 |

| Tape reforence woight(kg/㎡) | 18 | 19.5 | 22.5 | 24 | 25.9 | 31.8 | 36.1 | 40.4 | 43.8 | 45 | 45 | 50.7 | 53.4 | 59.6 | 63.7 | 68.7 |

| The width(mm) | The number of cords | |||||||||||||||

| 800 | 75 | 75 | 63 | 63 | 63 | 63 | 50 | 50 | 50 | |||||||

| 1000 | 95 | 95 | 79 | 79 | 79 | 79 | 64 | 64 | 64 | 64 | 59 | 55 | 55 | 54 | 49 | 45 |

| 1200 | 113 | 113 | 94 | 94 | 94 | 94 | 76 | 77 | 77 | 77 | 71 | 66 | 66 | 63 | 59 | 54 |

| 1400 | 133 | 133 | 111 | 111 | 111 | 111 | 89 | 90 | 90 | 90 | 84 | 78 | 78 | 74 | 69 | 63 |

| 1600 | 151 | 151 | 126 | 126 | 126 | 126 | 101 | 104 | 104 | 104 | 96 | 90 | 90 | 85 | 80 | 72 |

| 1800 | 171 | 143 | 143 | 143 | 143 | 114 | 117 | 117 | 117 | 109 | 102 | 102 | 96 | 90 | 82 | |

| 2000 | 159 | 159 | 159 | 159 | 128 | 130 | 130 | 130 | 121 | 113 | 113 | 107 | 101 | 91 | ||

| 2200 | 176 | 141 | 144 | 144 | 144 | 134 | 125 | 125 | 118 | 111 | 100 | |||||

| 2400 | 193 | 155 | 157 | 157 | 157 | 146 | 137 | 137 | 129 | 121 | 109 | |||||

| 2600 | 209 | 168 | 170 | 170 | 170 | 159 | 149 | 149 | 140 | 131 | 119 | |||||

| 2800 | 230 | 184 | 184 | 184 | 184 | 171 | 161 | 161 | 151 | 142 | 129 | |||||

| 3000 | 247 | 198 | 198 | 198 | 198 | 185 | 174 | 174 | 148 | 152 | 138 | |||||

| 3200 | 246 | 211 | 211 | 211 | 211 | 198 | 186 | 186 | 158 | 162 | 147 | |||||

Cover rubber performance:

| Test items | Performance indicators | |||||||

| GB9770-2001 | DIN22131 | |||||||

| D grade | H grade | L grade | P grade | W grade | X grade | Y grade | ||

| The tensile strength | mpa≥ | 18 | 25 | 20 | 14 | 18 | 25 | 20 |

| Tensile elongation | %≥ | 400 | 450 | 400 | 350 | 400 | 450 | 400 |

| Taging test(70℃,7days), the change rate tensile strength Tensile elongation change | % | -25~+25 | -25~+25 | -25~+25 | -25~+25 | -25~+25 | -25~+25 | -25~+25 |

| Abrason quantity | ≤ | 90mm3 | 120mm3 | 150mm3 | 200mm3 | 90mm3 | 120mm3 | 150mm3 |