Description

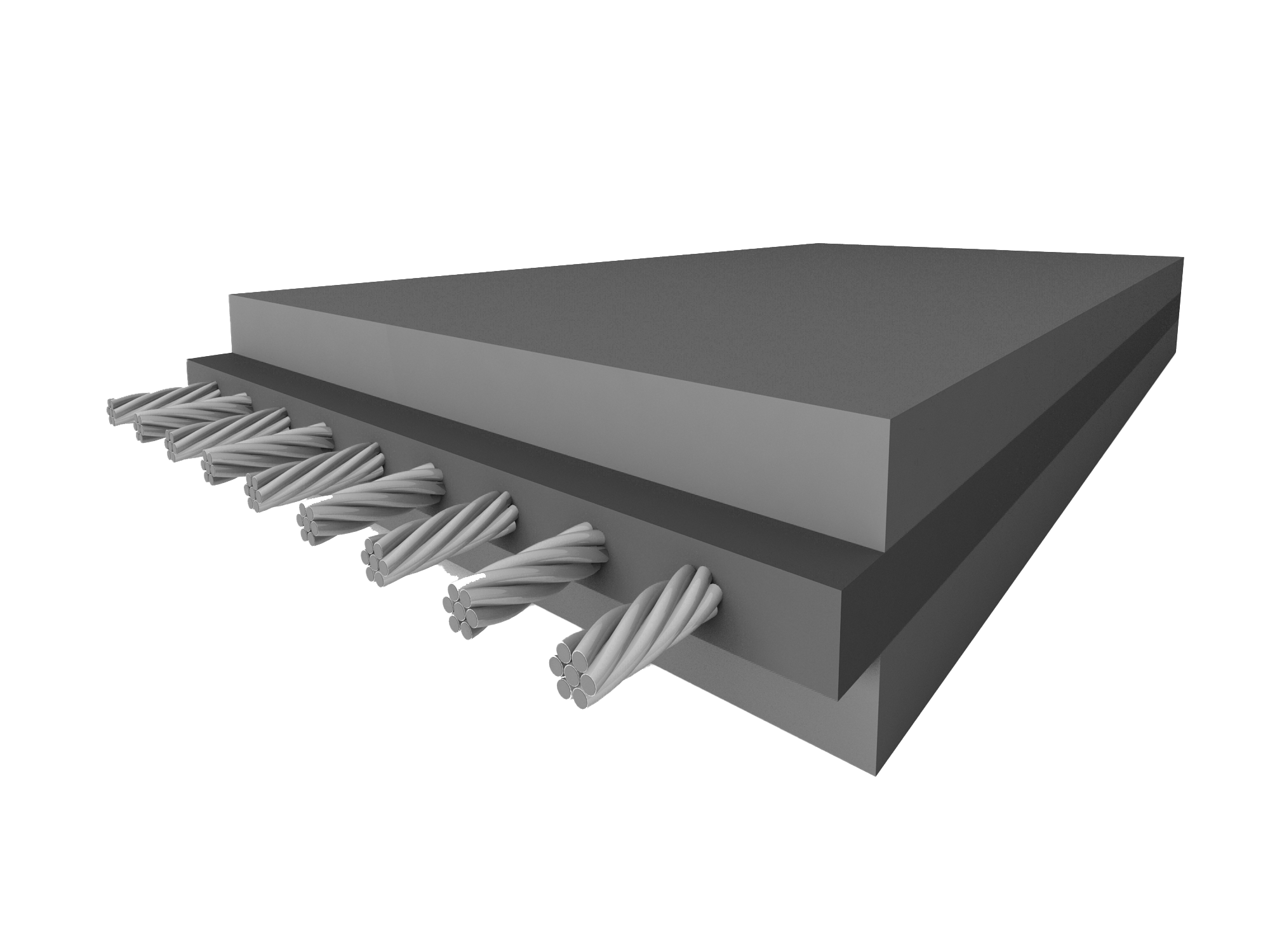

This energy saving conveyor belt internal friction or asymmetrical tension between idler and conveyor belt consumes energy.

Special rubber compounds and belt designs, for instance an additional transverse reinforcement – reduce the indentation and let the belt run easier over the idlers. Such belt types, on long distance conveyors, can save a lot of money.

They are called as LRR conveyor belt, XLL conveyor belt or EOB conveyor belts.

Usage:

It’s suitable for long-distance transportation of materials in mines, ports, electricity, chemical industries, coalmines etc.

Characteristics

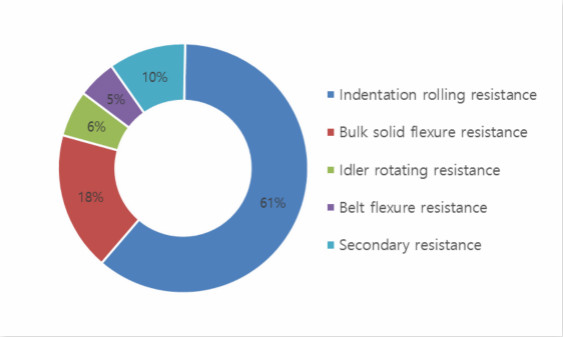

According to the research in recent years, about 61% of the energy consumption of the total driving energy consumption by the conveyor belt in the horizontal direction is used to overcome the indentation rolling resistance of conveyor belt in passing rollers and pulleys.

The viscoelastic property of the belt itself is the essential factor to produce indentation rolling resistance. By reducing the indentation energy loss to reduce energy loss, used as the low rolling resistance rubber at pulley side.

The cover can be divided into the following types in accordance with its usage.

LRR: General low rolling resistance rubber, which will save approximately 15% of energy in entire conveying system.

SLRR:Super low rolling resistance rubber, which will save approximately 20% of energy in entire conveying system.

FLRR:A low rolling resistance rubber with general flame resistant property.