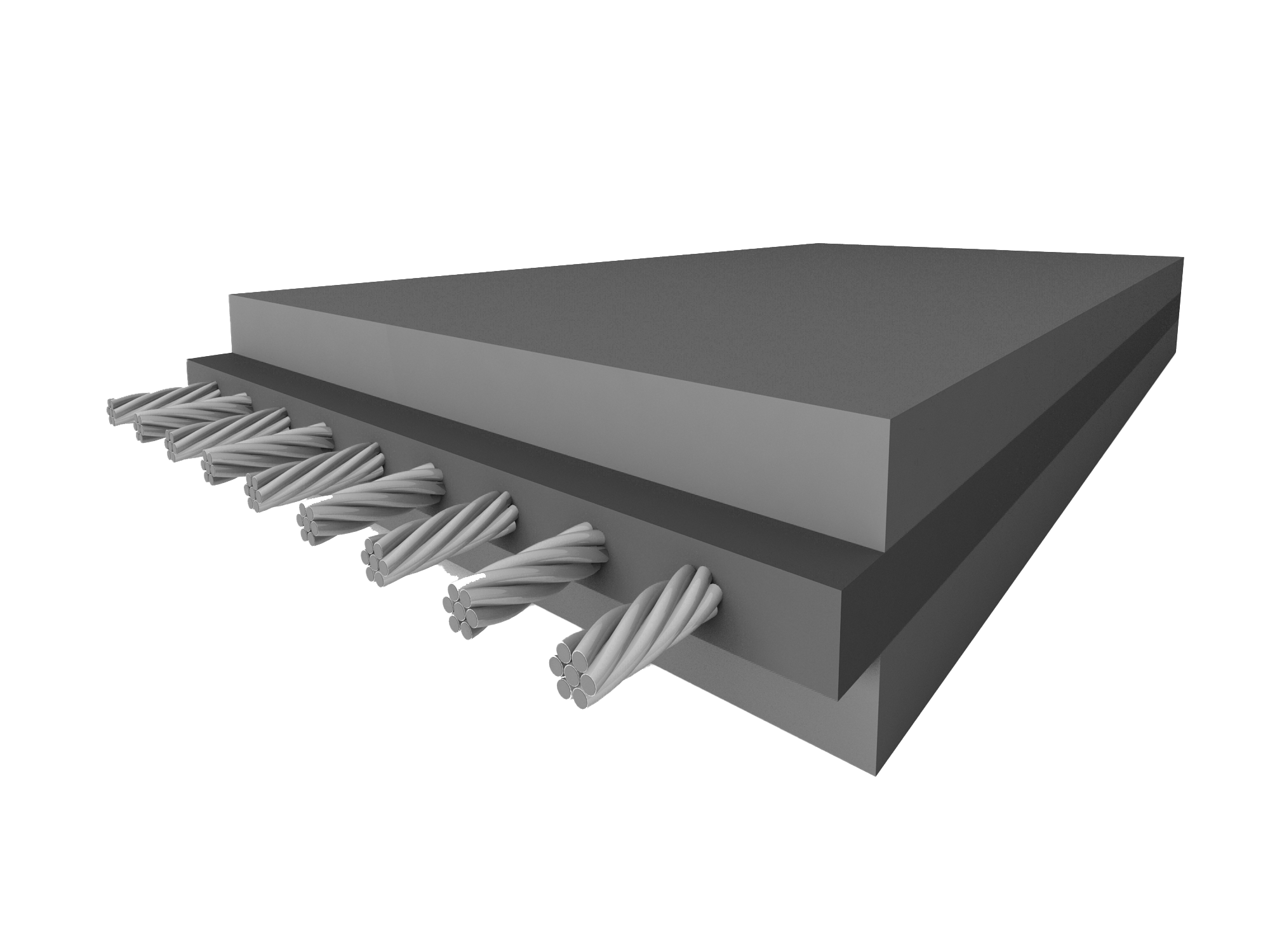

Description

Flame resistant steel cord conveyor belt range includes conventional K, S and V grades, but also complies with additional specific international and national standards as below:

K: Flame retardant cover according to ISO 340 and anti-static properties according to ISO 284. For general use with electrical and fire safety requirements in line with EN 12882 as well as the former German grade K as defined in DIN 22131 and DIN 22102.

S: Flame retardant cover and carcass according to ISO 340, anti-static according to ISO 284. For general use with electrical and fire safety requirements in line with EN 12882 as well as the former German grade S as defined in DIN 22102.

V: Flame retardant cover for underground use with electrical and fire safety requirements to EN 14973 and for general use with electrical and fire safety requirements in line with EN 12882.

Features:

Pass Qualitative Standard for Flame Resistance of Conveyor Belts

Made with a special formulation of natural and synthetic rubber, with added flame retardant properties

Self-extinguishing properties

Applications:

Underground mining

Hard rock mining

Cement industry

Grain and sugar industries

Mineral processing plants

Overland conveyors

Paper and wood industries

Port operations

Power and heating plants

Recycling industry

Steel industry

Tunneling

Flame Property Test:

Drum Friction Test

The drum friction test simulates a belt slipping over a jammed pulley, or a pulley rotating under a stationary conveyor belt. This measures whether the surface temperature remains under a required maximum after a specific time and under a specific tension.

Generally a rubber conveyor belt can produce a pulley surface temperature of up to 500°C (930°F). The visual appearance of flame or glow is not permitted.

Surface Resistance Test

An electrostatic charge may build up on the conveyor belt surface and ignite a mixture of flammable gases and air.

Therefore the surface resistance of the conveyor belt covers has to be below 300 MOhms.

Propane Burning Test

Conveyor belt must not conduct fire. In order to determine whether a conveyor belt fulfills this requirement, it is ignited by a propane burner. After the ignition source has been removed, the flames must self-extinguish within a certain time frame or within a certain distance. A typical sample for this test is 2 m long at full width.

Gallery Test

A small scale version of the Propane Burner Test, first described in DIN 22118.