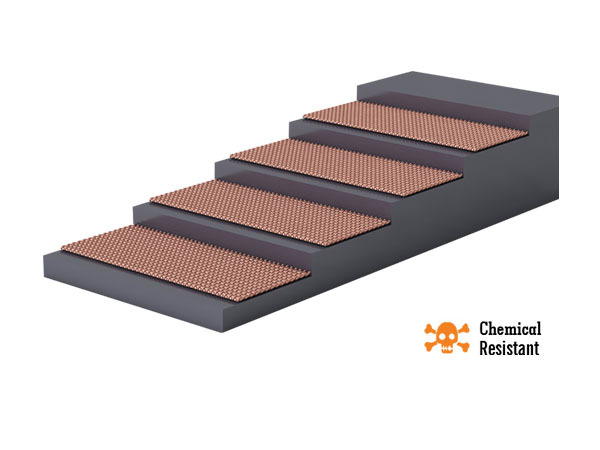

Description

Chemical Resistant Conveyor belting(also called acid and alkali resistant conveyor belt) solutions delivered feature use of superior rubber cover that is made from chemical resistant material and has fine anti-chemical corrosiveness. Also featuring optimum physical properties, these belts are developed using materials that do not dissolve, expand as well as corrode the belt, thus making these suitable for conveying material with chemical corrosiveness in:

Chemical factory

Chemical fertilizer factory

Paper mills

Belting for Mining Industry

Fertilizer industry

Cement Industry Belting

In other areas requiring conveying of acid/alkali-forming materials

Characteristics:

These conveyor belts feature superior chemicals and corrosion resistant properties

Having superior elasticity as well as small elongation at rated load

Have superior adhesion, flexibility as well as trough ability

Resistant to most chemicals including chlorinated compounds, acids & bases, coolant oils

Why Used:

These Acid as well as alkali resistant conveyor belts are used for conveying corrosive material that comprises acid as well as alkali in an industrial and mining working environment as well as in fertilizer plants, paper mills and chemical plants. Some of the characteristics of these belts that make these preferably used include:

Have superior bonding properties with no layer separation

Use of cotton, polyester-cotton, nylon and other material based belt cores that adds to the durability factor as well as resistance from chemicals