Description

Cross Rigid belts are rigid across the belt (fill or weft direction) but remain flexible the length of the belt (warp direction) in order to wrap the pulleys. Cross Rigid belts add mono-filament cross members to the standard conveyor belt fabric to increase the cross belt rigidity.

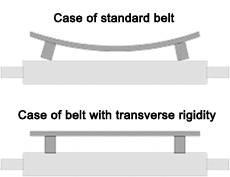

The increased rigidity prevents the belt from bowing or sagging during operating tensions caused by changes in horizontal/vertical direction and when supported on the return run from the edge of the belt.

Cross Rigid belts resist the side-to-side flexing normally found in conventional conveyor belting, while maintaining the flexibility to allow normal movement around standard pulley diameters.

Advantages:

Able to handle transitions while maintaining cross width stability.

Able to take conveyor up a steeper incline when combined with cleats and sidewall.

More flexibility with conveyor design.

Application:

High incline conveyors

Conveyors with transitions from horizontal to vertical

Belt Composition:

X=Cross-Stabilized Construction

E=Polyester Tension Plies

Rip Stop Conveyor Belt provides a special rip stop breaker inserted in top cover, this rip stop breaker has different material and specification that meet various conveying design requirement.

Features:

Good troughing index

Good flexibility without increasing pulley diameter