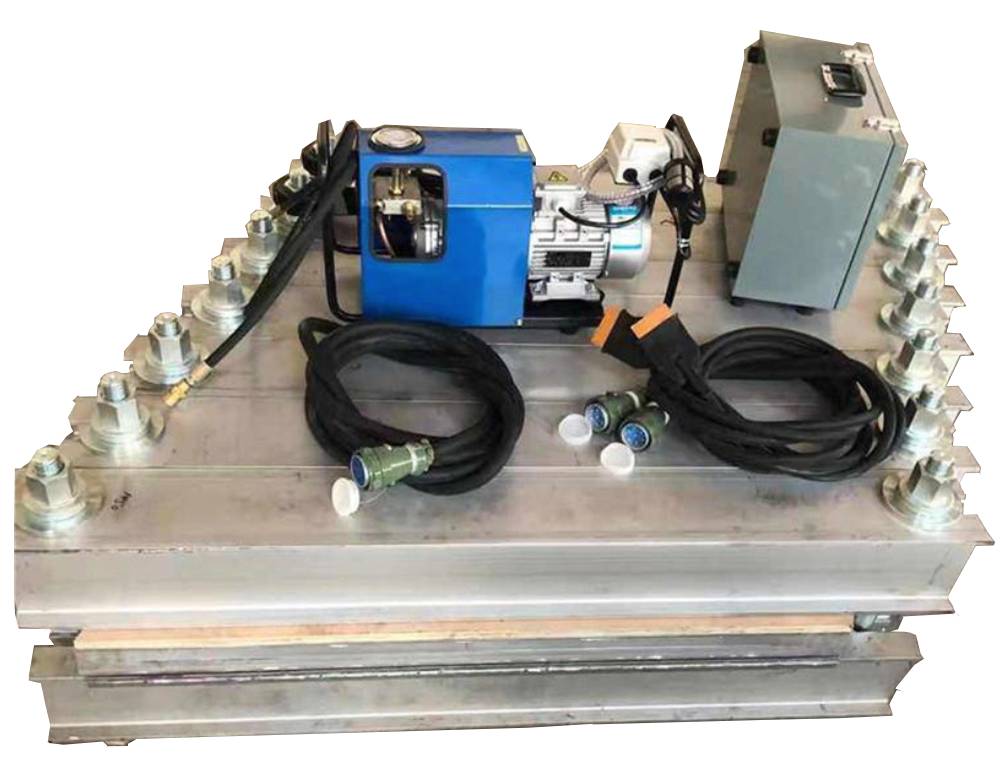

Description

The hot vulcanize machine is mainly made of aluminum and used for the splicing of rubber conveyor belts including EP, NN Steel cord belts, etc. It can be widely used in metallurgical plants, mines, electric power plants docks, etc.

Technical parameters:

Vulcanize pressure: 1.5 Mpa (15 kg / cm2) ;1.8 Mpa (18kg / cm2) also available;

Vulcanize temperature: 145° C (adjustable);

Temperature-rising time: within 40 min;

Temperature difference on the working surface: ±3° C

Adjusting range of temperature from temperature regulator: 0 ~ 200° C

Power voltage: 380V/50 Hz, or 660 V.

Standard Specification:

| Width of conveyor belt (mm) |

Power (kW) |

Sizes of heat plate L x W (mm) |

Assembled size L x W x H (mm) |

Weight of heaviest part (kg) |

| 650 | 9.84 | 830 x 820 | 139 x 830 x 580 | 59 |

| 800 | 11.46 | 830 x 980 | 1561 x 830 x 580 | 70 |

| 1000 | 14.4 | 830 x 1205 | 1751 x 830 x 580 | 83 |

| 1200 | 16.02 | 830 x 1415 | 2001 x 830 x 725 | 101 |

| 1400 | 18.96 | 830 x 1640 | 2251 x 830 x 725 | 113 |

| 1600 | 22.2 | 830 x 1850 | 2370 x 830 x 895 | 126 |

| 1800 | 23.94 | 830 x 2055 | 2601 x 830 x 895 | 143 |

| 2000 | 26.76 | 830 x 2290 | 2801 x 830 x 895 | 162 |

| 2200 | 29.7 | 830 x 2510 | 3101 x 830 x 895 | 174 |

Features:

Small in volume;

Light in weight;

Easy handling.