Description

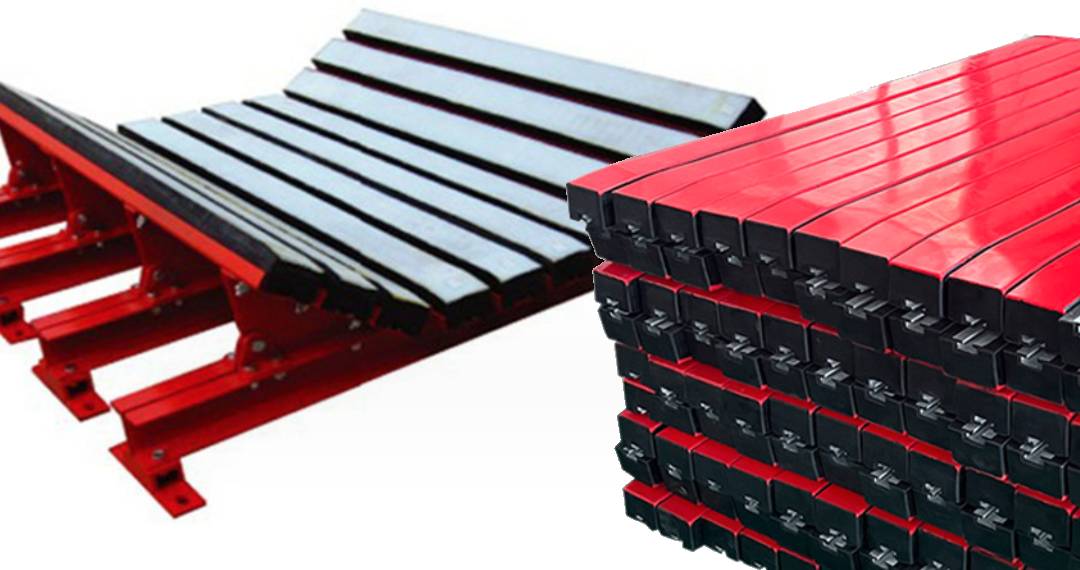

Impact Bed is composed of Impact Bar, and Impact Bar mainly uses an excellent high-elastic special rubber layer to fully and effectively absorb the impact of falling materials, greatly reducing the impact of falling materials on the conveyor belt, and truly improving the dropping point. Stress conditions. It also uses a special UHMW polymer polyethylene surface to minimize the friction coefficient between the conveyor belt and the Impact Bar and has good wear resistance.

PRODUCT PARAMETER OF IMPACT BED:

Name: Impact Bed

Material: UHMW-PE, rubber, aluminum alloy

Conveying capacity: 1≥6000T/H

Adaptable bandwidth: B=650-2000 MM

Adaptable belt speed: V≥4.5M/S

Specifications: determined according to the buffer bandwidth, length, conveying medium, particle diameter, belt speed, and transportation volume (can be customized)

Function: reduce impact, protect conveyor belt

Application scope: belt conveyor

PRODUCT PARAMETER OF IMPACT BAR:

Name: Impact Bar

Material: Made of polyethylene, rubber, and galvanized steel. The smooth surface of polyethylene reduces friction when the conveyor belt is running. The arc-shaped design on the surface of the polyethylene layer allows the conveyor belt to run smoothly. Highly elastic rubber layer which absorbs the impact of materials to the maximum extent. Effectively eliminates material splashing and leakage caused by uneven stress on the conveyor belt, shortens downtime to a minimum and effectively improves production efficiency.

Advantages of Impact Bat: Not easy to break, not easy to wear, smooth surface, high resilience

Technical data of Impact Bar:

| tensile strength | 30 MPa |

| Elongation at break | 300% |

| hardness | 96-98 Shore A |

| proportion | 30.93-0.94 g/cm |

| Friction coefficient | 0.07 |

| High molecular weight polyethylene color | white/blue/black |

| Flame retardant impact bar product parameters | |

| Length mm Thickness mm Height m | |

| 800 100 50/65/75/100 | |

| 1000 100 50/65/75/100 | |

| 1200 100 50/65/75/100 | |

| 1200 100 50/65/75/100 | |

| 1400 100 50/65/75/100 | |

| 1500 100 50/65/75/100 | |

| 1524 100 50/65/75/100 | |

| 1600 100 50/65/75/100 | |

| 1800 100 50/65/75/100 |

Mingsen can process and produce according to the drawings according to the customer’s needs. The original purpose of the Impact Bed design is to fully protect the conveyor belt and extend its service life during heavy blanking.