Description

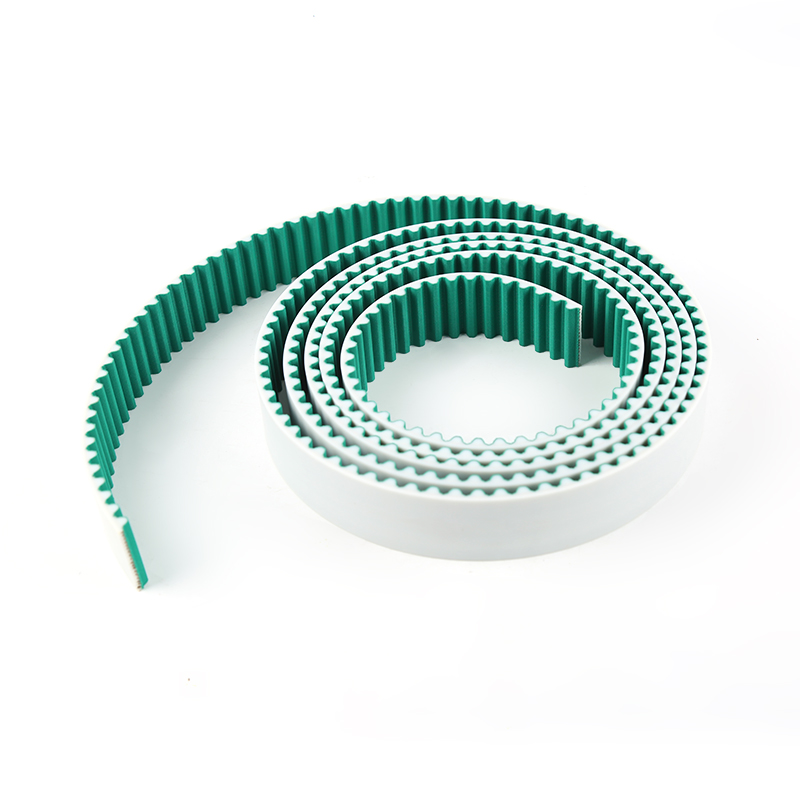

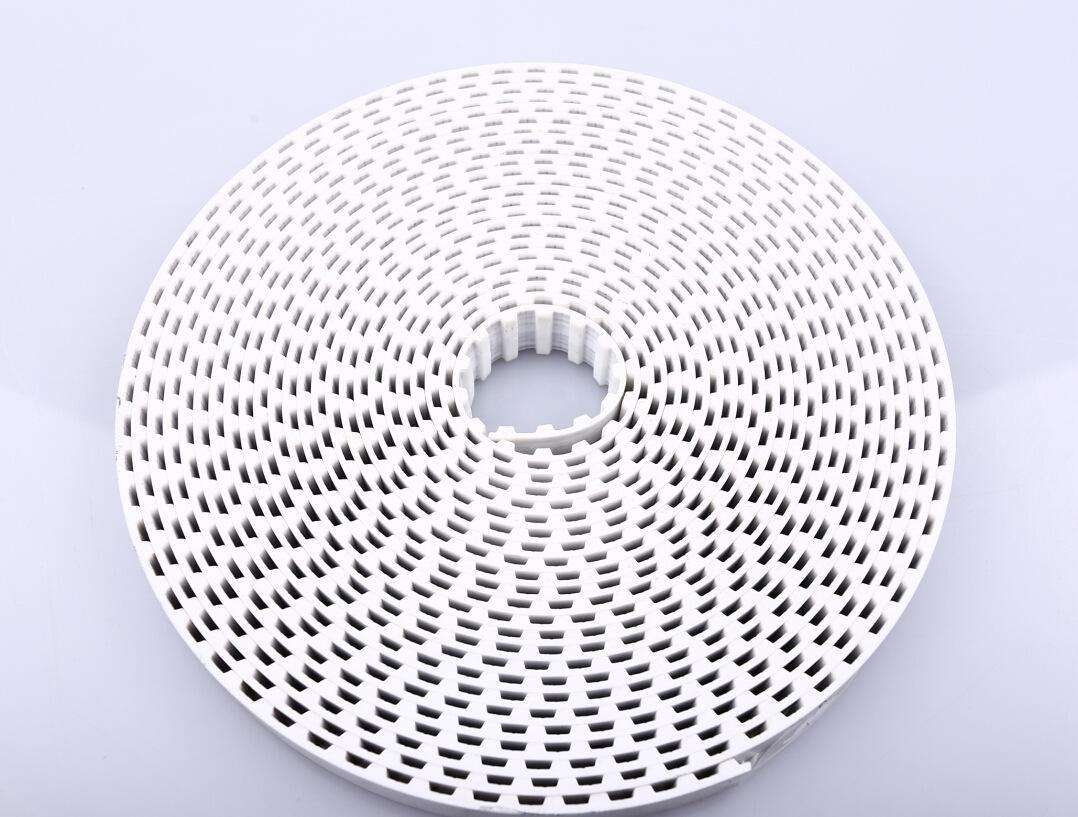

Mingsen PU Timing belts of the profile systems T and AT are made of polyurethane with high-tension fine steel cord tension members in most cases. As far as certain forces are given in this document, these values are only valid for these kinds of belts. For polyurethane belts with different tensile cords, i.e. aramid or rubber belts reinforced with glass fibre, the values can be different.

Open belts made of thermoplastic polyurethane can be spliced to work as endless belts in conveyor applications. In this case, the tolerances are not valid for the splicing area of the endless spliced belt.

Belt profile systems

Eight belt profiles for synchronous drives are standardized:

Profile system T: profile T2,5 profile T5, profile T10, profile T20 ;

Profile system AT: profile AT3, profile AT5, profile AT10, profile AT20

Belt tooth dimensions and tolerances

The nominal belt tooth dimensions are the same for single-sided and double-sided belts; they are given in Table 1 and shown in Figure 1

| Belt profile | Pitch Pb mm | Tooth Angle 2β Degrees | Root Width Sr mm | hs mm | hd mm | ht mm | ra min. mm | rr±0.1 mm |

| T2.5 | 2.5 | 40±2 | 1.5±0.05 | 1.30±0.15 | 1.90 | 0.7±0.05 | 0.2 | 0.2 |

| T5 | 5 | 40±2 | 2.65±0.05 | 2.20±0.15 | 3.25 | 1.20±0.05 | 0.4 | 0.4 |

| T10 | 10 | 40±2 | 5.30±0.1 | 4.50±0.30 | 6.8 | 2.50±0.10 | 0.6 | 0.6 |

| T20 | 20 | 40±2 | 10.15±0.15 | 8.00±0.45 | 12.85 | 5.00±0.15 | 0.8 | 0.8 |

| AT3 | 3 | 50±2 | 1.5±0.05 | 1.90±0.15ª | n.a | 1.10±0.05 | 0.3 | 0.1 |

| AT5 | 5 | 50±2 | 2.50±0.05 | 2.70±0.15ª | 3.05 | 1.20±0.05 | 0.4 | 0.6 |

| AT10 | 10 | 50±2 | 5.00±0.1 | 4.50±0.30ª | 6.5 | 2.50±0.10 | 0.6 | 1.2 |

| AT20 | 20 | 50±2 | 10.00±0.15 | 8.00±0.45ª | 12.15 | 5.00±0.15 | 1.6 | 2.5 |

| NOTE The value of hd can vary due to process-related adjustments of the manufacturer.

ª The thickness of the backside depends on the method of manufacturing. |

||||||||

Belt widths and tolerances (mm)

| Belt Profile | Nominal Belt Width | Tolerance | |||

| T2,5

T5 T10 T20 AT3 AT5 AT10 AT20 |

-

6 16 32 6 6 16 32 |

4

10 25 50 10 10 25 50 |

6

16 32 75 16 16 32 75 |

10

25 50 100 25 25 50 100 |

±0,3

±0,5 ±0,5 ±1,0 ±0,3 ±0,5 ±0,5 ±1,0 |

| NOTE Tolerances for larger belt widths and closer tolerances to be confirmed between the user and the manufacturer. | |||||

APPLICATIONS

. Office-ATM machines

. Appliances

. Laundry machines

. Medical equipment

. Machine tools, Packaging machines, Plastic machines

. Woodworking and glass machines

. Compressors, pumps, ventilation

. Paper industry machinery

. Food processing equipment

. HVAC units

. Textile machinery

. Mining equipment

. Farm machinery, Vending machinery

. Automatic warehouses

KEY FEATURES & BENEFITS

- Good quality/price ratio

- Maintenance-free

- High efficiency

- Good oil resistance

- Temperature: – 20/+100 ‘C

Belt nomenclature

belt is designated by a combination of numbers and letters as follows:

- a) the width, in millimetres;

- b) the profile system;

- c) the pitch, in millimetres;

- d) the belt pitch length, in millimetres (and add the number of teeth in brackets, if required);

- e) double-sided belts are designated by adding DG or DT before the profile system letter: DG if the tooth position is opposite Gap; DT if the tooth position is opposite Tooth;

- f) open belts are designated by adding the letter “M” behind the length; for spliced belts, use the letter “V.”

EXAMPLE 1.

A metric synchronous belt of 10 mm pitch, profile system T, 50 mm wide, and 1 400 mm in pitch length is designated as follows:

for a single-sided belt: 50- T10- 1 400;

for a double-sided belt: 50- DG- T10- 1 400 or 50- DT-T10- 1 400.

EXAMPLE2 A metric synchronous belt of 5 mm pitch, profile system AT, 25 mm wide, and 500 mm in pitch

length (number of teeth = 100) is designated as follows:

for a single-sided belt: 25 – AT5 – 500 (100 t);

for the double-sided belt: 25 – DG – AT5 – 500 (100 t) or 25 -DT- AT5 – 500 (100 t).