Description

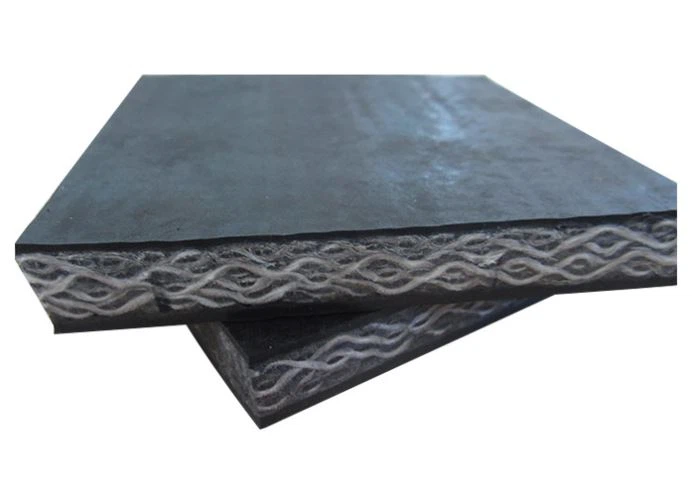

Classification of solid woven conveyor belt

PVC stands for the solid woven conveyor belt with PVC cover.

Non pressed PVC type is suitable for applications in dry conditions at a slope angle of no greater than 16 degrees. The belt is non-pressed with cover no more than 0.8mm.

Pressed PVC type, both top and bottom covers are PVC, thickness of each side can be up to 4mm, the belt has much more advantages than non pressed PVC belt on impact resistance, water soaking, with longer service life, higher fastener holding.

Features

Low stretch

Low maintenance

Anti-static

Flexible

Lightweight

Impervious to moisture, acids, oils, gases, sunlight

Excellent fastener holding

Excellent resistance to tearing, peeling and impact

Endless belt splicing

Special wear resistant edge design

PVG stands for the solid woven belt with PVG cover (nitrile rubber)

PVG type is covered with covers mainly composed of rubber, which further improves the troughability, resistance to wetness and slip, resistance to low temperature, elongation and wear resistance of the belt. Both top and bottom cover are PVG, the belt can be used to carry materials mixing some water at the slope no more than 20°,elongate life of belt

Characteristics

Anti slide caused by wetness good climbing capacity

Low-temperature resistant

Good elasticity, anti-impact

Low elongation at rated load ,suitable for long distance conveying

Tear resistant, good flexing capacity

Long service life

Production standards usually applied: DIN22109, AS4606, BS3289, BC158 MT914, etc

Main physical properties:

| Item | Tensile strength | Carcass thickness |

Carcass weight |

Minimum tear force |

Elongation at break | Cover grade and recommended thickness |

Belt width | Recommended min pulley diameter |

|||

| (min) (N/mm) | (mm) | (Kg/m2) | (N) | (min)(%) | (mm) | (mm) | (mm) | ||||

| Warp | Weft | Warp | Weft | Pressed PVC | PVG | ||||||

| 680/1 | 680 | 265 | 6.5 | 8.5 | 1090 | 15 | 18 | 1.5+1.5 | 1.5+1.5 | 500-2200 | 400 |

| 800/1 | 800 | 320 | 6.9 | 9 | 1180 | 15 | 18 | 1.5+1.5 | 1.5+1.5 | 500 | |

| 1000/1 | 1000 | 350 | 7.5 | 9.7 | 1180 | 15 | 18 | 2+1.5 | 2+1.5 | 630 | |

| 1250/1 | 1250 | 350 | 8.5 | 11 | 1540 | 15 | 18 | 2+2 | 2+1.5 | 750 | |

| 1400/1 | 1400 | 350 | 9 | 11.5 | 1540 | 15 | 18 | 3+2 | 2.5+1.5 | 750 | |

| 1600/1 | 1600 | 450 | 9.5 | 12.3 | 15 | 18 | 3+2 | 2.5+1.5 | 800 | ||

| 1800/1 | 1800 | 450 | 10 | 13 | 15 | 18 | 3+2 | 3+2 | 800 | ||

| 2000/1 | 2000 | 450 | 10.5 | 13.6 | 15 | 18 | 3+2 | 4+2 | 1000 | ||

| 2500/1 | 2500 | 450 | 12.5 | 14.5 | 15 | 18 | 3+2 | 5+3 | 1200 | ||

| 3100/1 | 3100 | 450 | 17 | 17 | 15 | 18 | 1500 | ||||

| 3500/1 | 3500 | 500 | 20 | 19 | 15 | 18 | |||||

Minimum Conveyor Rollers’ Diameter Recommended:

| Model | 680S | 800S | 1000S | 1250S | 1400S | 1600S | 1800S | 2000S | 2240S | 2500S |

| Min. Conveyor Rollers’ Diameter(mm) |

630 | 630 | 630 | 800 | 800 | 1000 | 1000 | 1250 | 1250 | 1400 |