Description

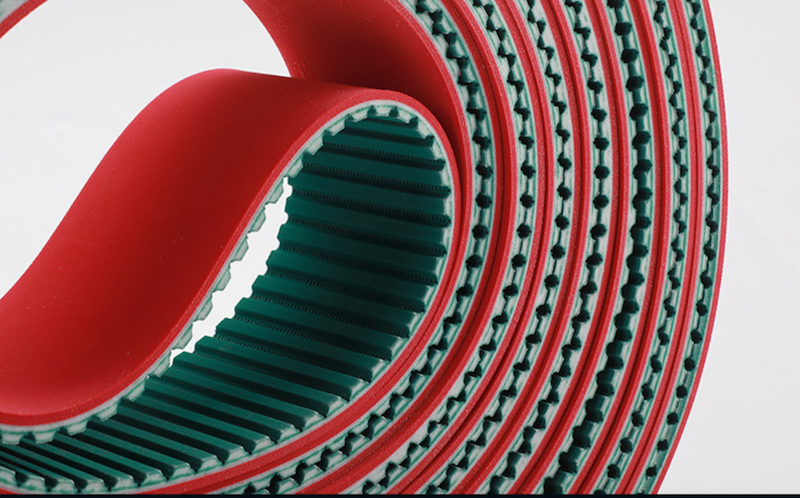

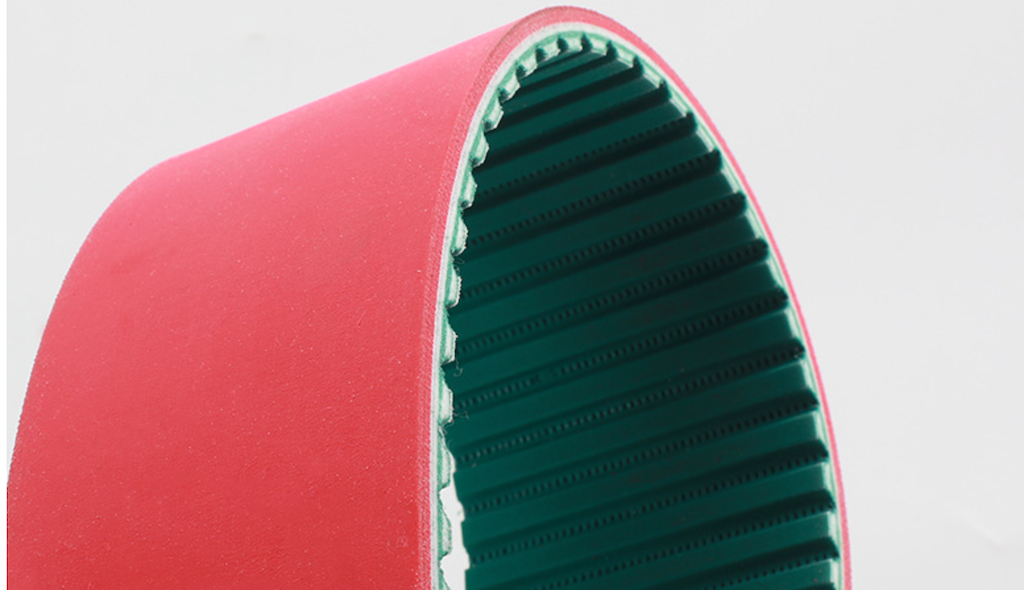

PU Top Coated Single Sided Timing Belts are made of thermoplastic polyurethane material, and cover Linatex or silicone on the back. Skeleton applies steel wire or aramid cord to ensure the sound drive properties, accurate and smooth drive. It functions as drive and transfer.

Material:

- Steel wire core is used inside the PU belt, Tooth shape and size are optimized. It can ensure uniform load distribution and small deformation. The teeth of polyurethane timing belts have high shear resistance. Good wear and oil resistance.

- PU Top Coated Single Sided Timing Belts which has high hardness and strong tensile strength, suitable for high-intensity transportation. Good acid resistance, aging resistance, and excellent ozone performance; Operating temperature range -10°C to 80°. For ultra-low temperatures, composite materials are available on request

Additional options:

•Toothed cloth/NFT

•Back cloth/NFB

•Double-sided cloth/NFT+NFB

•Gluing/Covering

-Double sides

| Model | b [mm] |

M type Ftzul [N] |

V type Ftzul [N] |

M type Fbr [N] |

Weight [kg/m] |

| T5 | 25 | 810 | 405 | 3150 | 0.053 |

| AT5 | 25 | 1656 | 828 | 5589 | 0.09 |

| T10 | 25 | 2385 | 1192.5 | 8694 | 0.11 |

| AT10 | 25 | 3753 | 1876.5 | 14535 | 0.15 |

| T20 | 25 | 3753 | 1876.5 | 14535 | 0.18 |

| AT20 | 25 | 4752 | 2376 | 17325 | 0.24 |

| XL | 25.4 | 810 | 405 | 3150 | 0.061 |

| L | 25.4 | 2484 | 1242 | 9072 | 0.098 |

| H | 25.4 | 2484 | 1242 | 9072 | 0.11 |

| XH | 25.4 | 3528 | 1764 | 13680 | 0.26 |

| HTD3M | 25 | 810 | 405 | 3150 | 0.05 |

| HTD5M | 25 | 2385 | 1192.5 | 8694 | 0.12 |

| HTD8M | 20 | 2871 | 1435.5 | 11115 | 0.14 |

| HTD14M | 25 | 4752 | 2376 | 17325 | 0.30 |

| RTD5M | 25 | 2385 | 1192.5 | 8694 | 0.12 |

| RTD8M | 20 | 2871 | 143500 | 11115 | 0.14 |

| RTD14M | 40 | 11475 | 5737.5 | 43200 | 0.48 |

| STD5M | 25 | 2385 | 1192.5 | 8694 | 0.12 |

| STD8M | 20 | 2871 | 1435.5 | 11115 | 0.13 |

| STD14M | 40 | 11475 | 5737.5 | 43200 | 0.48 |

| P1 | 20 | 630 | 315 | 2475 | 0.04 |

| P2 | 25 | 3753 | 1876.5 | 14535 | 0.08 |

| P3 | 25 | 6003 | 3001.5 | 21875.4 | 0.09 |

| P4 | 25 | 6120 | 3060 | 23040 | 0.11 |