Description

Top Coated Timing Belts drive is composed of a closed annular belt with equally spaced teeth on the inner circumferential surface and a corresponding pulley. During movement, the belt teeth mesh with the tooth grooves of the pulley to transmit motion and power. It is a meshing transmission, so it has various advantages of gear transmission, chain transmission, and flat belt transmission. Synchronous belt transmission has an accurate transmission ratio, is no-slip, can obtain a constant speed ratio, can be precisely transmitted, has stable transmission, can absorb shock, has low noise, and has a wide transmission speed ratio range. The compact structure is also suitable for multi-axis transmission, with small tension, no need for lubrication, and little pollution, so it can work normally in situations where pollution is not allowed and the working environment is harsh.

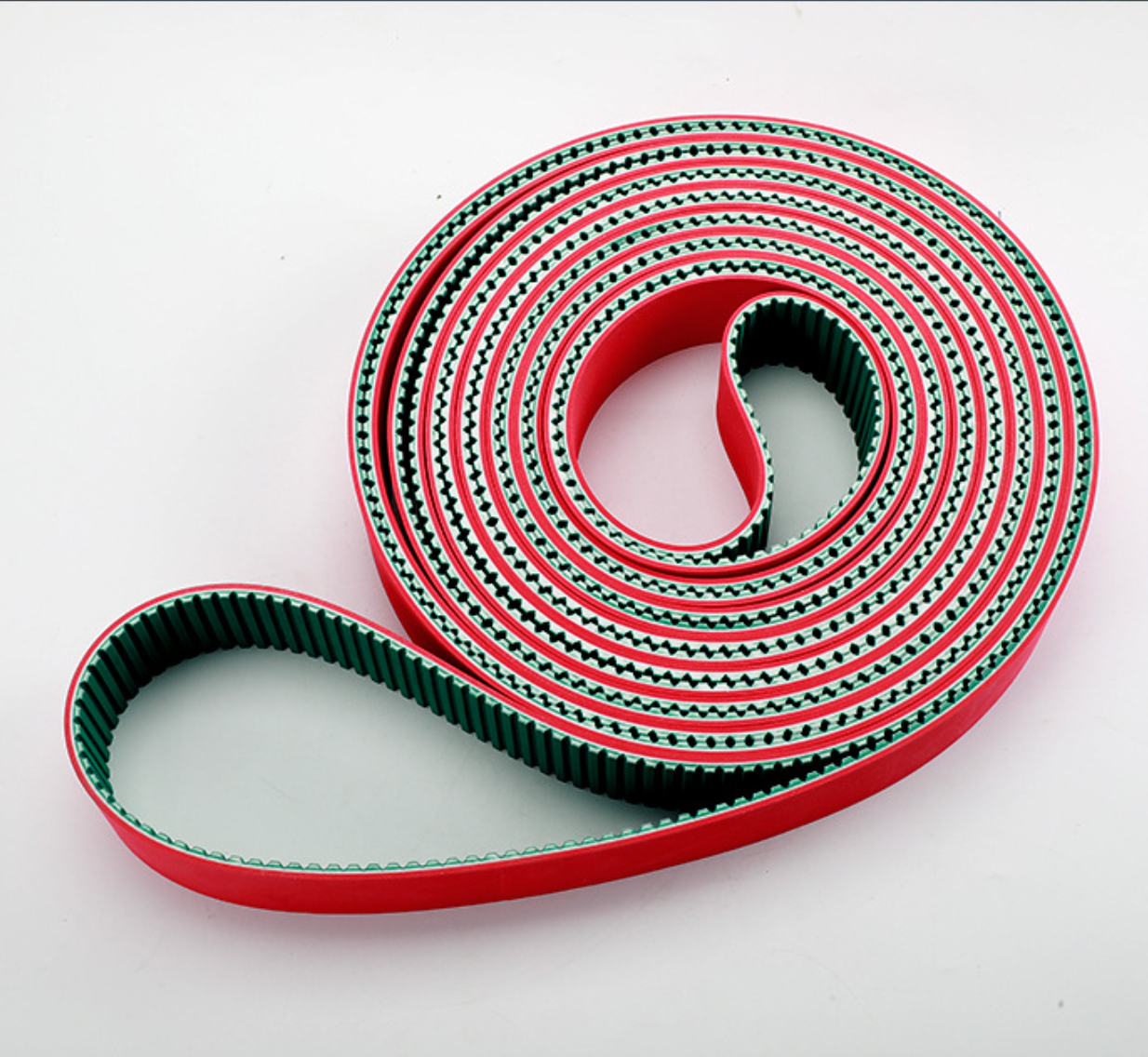

Add red glue on the back of the tooth surface cloth

Size: Support customization

Color: White/Black (can be customized)

Core: steel /Kevlar

Maximum width: 450mm

Standard length: 100m

Length tolerance: ±05mm/m

Thickness tolerance: ±0.2mm

Material:

PU Top Coated Timing Belts

High hardness and strong tensile strength, suitable for high-intensity transportation

Good acid resistance, aging resistance, and excellent ozone performance;

Operating temperature range -10°C to 80°

For ultra-low temperatures, composite materials are available at the request

Additional selections:

Toothed cloth/NFT

Back wrapping/NFB

Double bread cloth/NFT+NFB

Glue/Covering

Double sides

| Model | Belt Width b [mm] |

Allowable tensile load M type FTzul [N] |

Allowable tensile load V tpee FTzul [N] |

Breaking load M type FBr [N] |

Weight [kg/m] |

| T5 | 25 | 810 | 405 | 3150 | 0.053 |

| AT5 | 25 | 1656 | 828 | 5589 | 0.09 |

| T10 | 25 | 2385 | 1192.5 | 8694 | 0.11 |

| AT10 | 25 | 3753 | 1876.5 | 14535 | 0.15 |

| T20 | 25 | 3753 | 1876.5 | 14535 | 0.18 |

| AT20 | 25 | 4752 | 2376 | 17325 | 0.24 |

| XL | 25.4 | 810 | 405 | 3150 | 0.061 |

| L | 25.4 | 2484 | 1242 | 9072 | 0.098 |

| H | 25.4 | 2484 | 1242 | 9072 | 0.11 |

| XH | 25.4 | 3528 | 1764 | 13680 | 0.26 |

| HTD3M | 25 | 810 | 405 | 3150 | 0.05 |

| HTD5M | 25 | 2385 | 1192.5 | 8694 | 0.12 |

| HTD8M | 20 | 2871 | 1435.5 | 11115 | 0.14 |

| HTD14M | 25 | 4752 | 2376 | 17325 | 0.30 |

| RTD5M | 25 | 2385 | 1192.5 | 8694 | 0.12 |

| RTD8M | 20 | 2871 | 1435.5 | 11115 | 0.14 |

| RTD14M | 40 | 11475 | 5737.5 | 43200 | 0.48 |

| STD5M | 25 | 2385 | 1192.5 | 8694 | 0.12 |

| STD8M | 20 | 2871 | 1435.5 | 11115 | 0.13 |

| STD14M | 40 | 11475 | 5737.5 | 43200 | 0.48 |

| P1 | 20 | 630 | 315 | 2475 | 0.04 |

| P2 | 25 | 3753 | 1876.5 | 14535 | 0.08 |

| P3 | 25 | 6003 | 3001.5 | 21875.4 | 0.09 |

| P4 | 25 | 6120 | 3060 | 23040 | 0.11 |