Why do belt slip

What is belt slippage?

Belt slippage occurs whenever torque demand exceeds the available friction between a V-belt and one or more of the pulleys (sheaves). When this occurs, the belt begins to slide backwards a bit as it moves with the pulley. This action is similar in two ways to slightly slipping the clutch in a manual transmission car:

It is a variable effect, ranging from under one percent to ten percent and more; and The portion of RPM comprising slip is near-pure friction, which is converted to heat.

Why do belts slip?

There is a wide variety of reasons V-belts and pulleys slip. Some important reasons are:

WORN PULLEYS

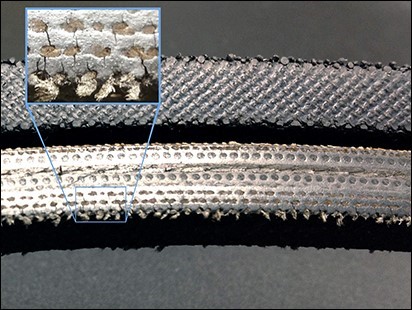

If belts become hard and glazed, and/or are operating in dusty environments, they can begin slipping in the V-grooves of conventional metal pulleys, abrading them in the process. Once a pulley’s V-profile has begun wearing and is no longer true, even brand-new replacement belts have a difficult time gripping; belts slip even more, accelerating the pulley-wear process. Expensive pulleys can be quickly ruined and—until replaced—will rapidly chew up replacement belts.

A severely worn agricultural pulley.

A worn and glazed conventional steel pulley.

HARDENED & GLAZED BELTS

V-belts are made of vulcanized rubber. Heat is their enemy. Vulcanized rubber is subject to “thermo-oxidation,” where oxygen from the air and high temperatures harden the belt. A belt hardens twice again faster each time its operating temperature increases another 10 degrees Celsius (18 °F). This is an insidious problem because if a belt slips just a little, it generates heat—the belt’s enemy—and it does so precisely at the belt’s mating surface! A harder belt slips even more, which generates still more heat. It is a runaway process that can be nearly impossible to interrupt once it has begun.

A new belt (top) and a glazed, cracked belt (bottom).

CONTAMINATION

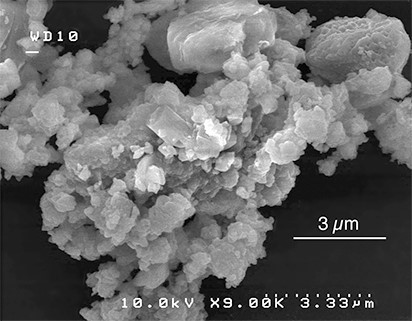

Particulates, whether they be mineral (dirt, silica, or quartz), agricultural (organic), or synthetic (hydraulic fluid, oil) can severely degrade belt/pulley friction. Particulate contamination behaves like both a lubricant and an abrasive. With a normal smooth metal pulley, particles have nowhere to go; they separate the belt from the pulley in microscopic zones. Once the belt begins to slip, these same particles now grind away at the pulley. This wear tends to rapidly occur because dirt and dust particles—even cellulosic agricultural particulates—are highly abrasive to ordinary steel pulleys.

Very fine, wind-blown dust (“ash”) from the 1980 Mt. St. Helens eruption.

HIGH LOAD DEMAND

Some types of equipment, such as those at a manufacturing plant, have carefully controlled and well-known loads running through belt-drive systems. For many other types of equipment, notably agricultural and rock crushing equipment, load demand is operator dependent. As operators try to be more productive (go a bit faster, for instance), their belts can begin slipping. The vicious circle (slip → heat → belt thermo-oxidation → less friction → increased slip → pulley wear → yet more slip) can doom operators to an inevitable—and expensive—phone call to their equipment dealer.

IMPROPER TENSION

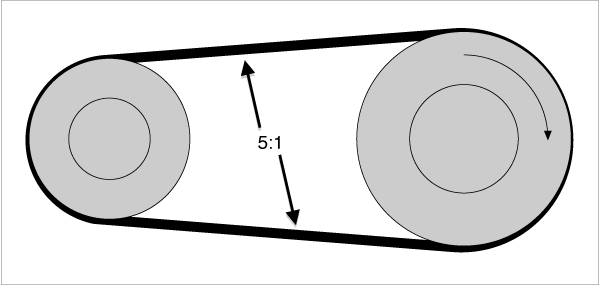

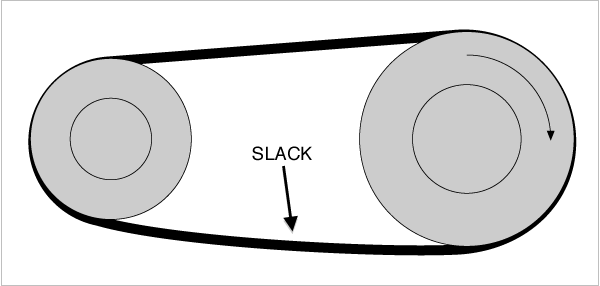

V-belts function well only in a surprisingly narrow range of tension. Shown below are two belt-drive systems.

In a properly tensioned pulley system, the taut side (top arrow) has five times the operating tension of the slack side (bottom arrow). This is the optimal “5:1 dynamic tension ratio.”

A surprisingly small reduction in belt tension yields a proportionally large reduction in slack-side tension. Slip rates wildly increase as the slack-side tension approaches zero.

Once belts become hot due to slippage, they expand. With severe slippage, even the most sophisticated belt tensioners can’t keep up and belts rapidly lose their optimal 5:1 dynamic tension ratio.